Calibrated tubes in stainless steel are the perfect products for manufacturers and suppliers of aeromodelling parts and also for the lovers of scale models who are looking for better performances of their aircrafts and guarantee the durability of the key pieces of the aircrafts.

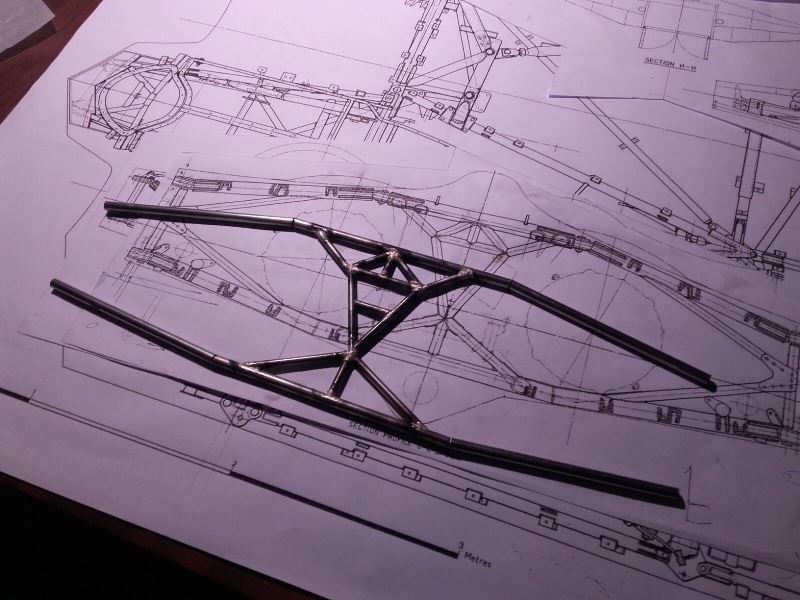

Calibrated tubes used for aeromodelling bring hardness to the long wings frameworks and to the fuselage. They are coupled with the inside part of the framework, in order to reinforce the whole structure of the aircraft model and to withstand the pressure of flight during takeoffs and landings. Calibrated tubes used for aeromodelling are also defined as capillary tubes and more precisely as axles, because of their small diameters, which is a fundamental characteristic to guarantee the lightness of the spar.

Calibrated tubes in stainless steel used for aeromodelling replace the lightweight wood framework of traditional aircraft models.

Calibrated tubes in stainless steel have brought a revolution in the aeromodelling sector. The new frameworks, made up with small diameter parts in stainless steel guarantee the durability of the aircrafts, including under extreme conditions. The impact of malleability due to the use of wood in the manufacturing of the framework has been reduced. Moreover, this makes repairs of aircraft models easier. Before, we had to replace the wings of the models after flight accidents or accidental shocks.

Calibrated tubes used for both wings spar or fuselage increase strength without adding any more weight.

Standard

capillary tubes in stainless steel used for aeromodelling are manufactured with

diameters going from 0.4mm to 9.0mm. The sizes vary

according to the scale of the aircraft, to the pressure it is going to withstand and also to the position of the metal rod in the model.

Precision tubes for aeromodelling arose as a need when scale models driven by turbines started to become popular. Their use also became common as tubes in stainless steel are used to design jet engines, but also for the pressure this drive method added to the wings. This steels are the most recommended metal profiles for the design of turbines, as they have a great resistance to high temperatures and pressures, bringing free movements and adjusted coefficient of expansion in return.

Calibrated tubes in stainless steel both technique and flight innovations, as vanguard aeromodelling is spreading.